Working machinery, hydraulic mechanical diesel engine, turbine, generator, fuel engine, various pumps, compressors, chillers, chemical industry, ship, vehicle and other industries, various mechanical industries, etc. the filter can be filtered and cleaned during operation.

characteristic:

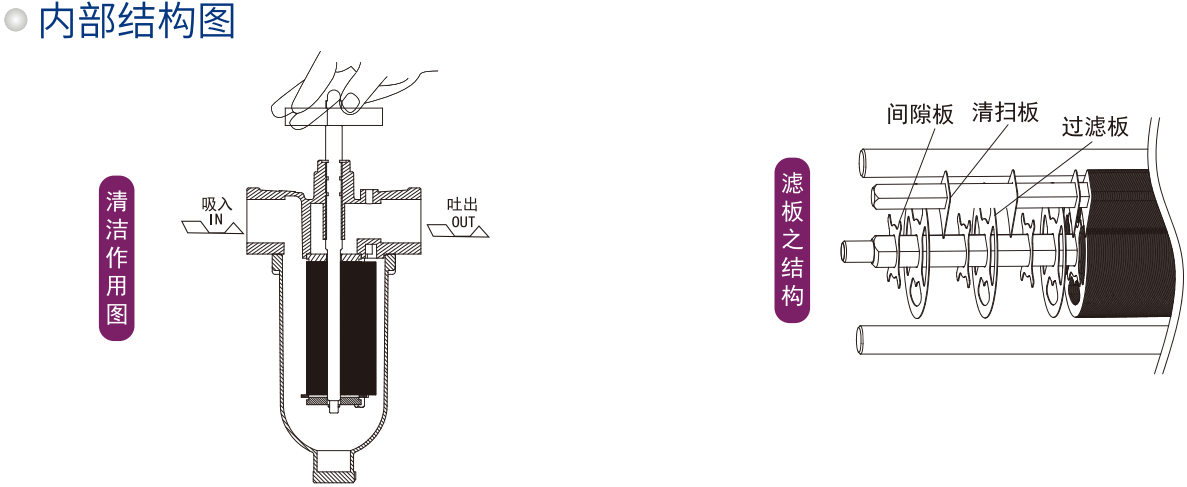

1. As long as the simple rotary handle is used, the filter mesh can be cleaned in the machine even when it is under

pressure, and at the same time, the machine and parts can continue to operate without interruption.

There is no need to worry about the reduction of oil delivery by filtration.

2. The filter surface will not be bent and deformed under the pressure back pressure.

It is firm and reliable, exquisite and precise, with large filtering area and excellent performance.

3. There is no lack of metal mesh and cloth woven filter, no fault, and it can be used for a long time.

4. It can be used as the circulation and reduction device of mechanical and mechanical pipes.

5. It is necessary for safe operation and improvement of functional efficiency, with high installation efficiency.

It is a foolproof automatic filter.

6. With negative pressure gauge (new type), it can directly reflect whether the oil is smooth or not.

lt can be widely used in :

This filter can filter impurities during operation in industries such as working machinery, hydraulic machinery, diesel engines, turbines, generators, fuel engines, various pumps, compressors, Freezer, chemical industries, ships, vehicles, and various mechanical industries.

The method ofimpurity cleaning :

Long-term operation of the oil contains a lot of particulate matter and impurities, when running particulate matter and impurities will be adsorbed on the filter element, do not clean up will cause the filter plug, need to regularly turn the filter handle, clean up the filter so that particulate matter and impurities fall at the bottom of the oil cup, each time at least 3-4 turns around the handle to clean up the impurities, after the rotation of the filter at the bottom of the plug unscrewed, so that the impurities at the bottom of the oil cup drop, after cleaning the plug screwed on, the filter is cleaned.

Notes :

when cleaning the impurities, it is best to let the oil pump motor stop running, and then run again when the impurities are cleaned up.